Automated Testing Equipment for Electronics

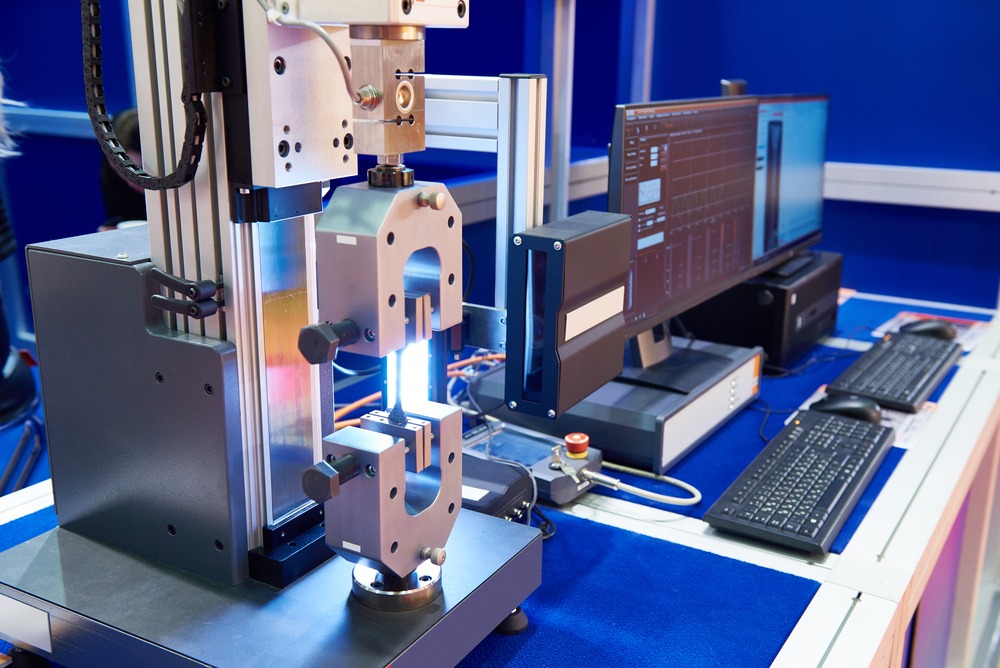

ATE stands for Automatic Test Equipment, or also Automated Test Equipment. ATE equipment usually lives in a rack and is used in a production environment to test products coming out of their manufacturing line for a pass or fail in electrical performance.

In general, the equipment is a very custom setup that can include some large expensive equipment. The main factor that makes all this equipment become ATE is that it is all controlled by a PC running custom test software.

What are the Components of an ATE System for Electronics?

Equipment can include power supplies, oscilloscopes, current sources, volt meters, current meters, RF signal generators, spectrum analyzers and RF power detectors or meters.

All of this equipment is tied together and controlled with a PC running custom test software written in Labview or other engineering based languages. The beauty of Labview is it is graphical and can be learned easily by electrical hardware engineers that aren’t necessarily great programmers. Connecting to the device under test is usually done with quick connectors for connectorized modules, or probes / bed of nails for devices without connectors.

How is ATE Useful and Beneficial?

Without an ATE setup, each part under test would need an engineer to manually enter in test criteria into the equipment, then manually measure and adjust equipment for each parameter under test while recording this information, plus determine if the part passes or fails.

Using ATE, an engineer programs all of these tests up front once. Then a technician hooks up the device under test and a PC manipulates all the equipment, measures the data and determines if it passes or fails.

Example of a Test Setup that Uses Automatic Test Equipment with RF Signal Sources

For an example, an RF filter could be tuned and tested with a couple of different methods. One would be to purchase a $50K+ Vector Network Analyzer:

The Network Analyzer could be controlled with a computer, which technically is what would make it Automated Test. But with a PC connected, there is not necessarily a need for a display and keyboard on the equipment making these features an added expense.

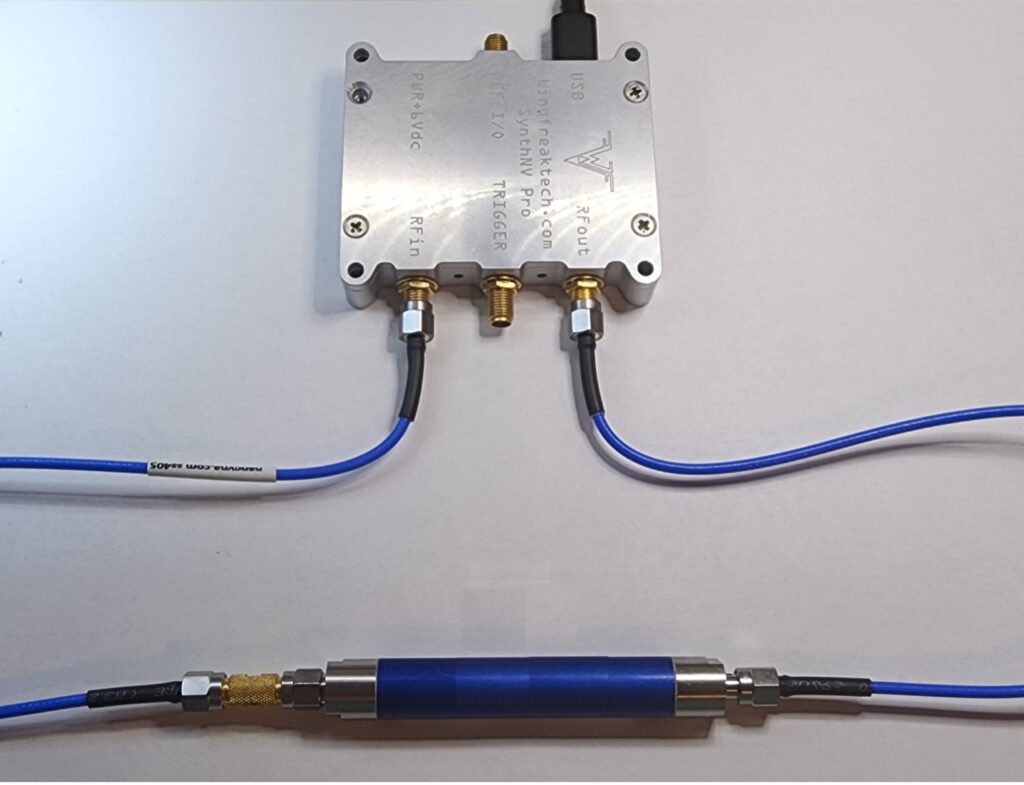

Newer technology has allowed manufacturers like Windfreak Technologies to provide a trimmed down, much lower cost solution such as the SynthNV Pro to test insertion loss of RF filters, amplifiers, and other RF devices. This allows an engineer to spend less money possibly enabling parallel test lines that speed up testing significantly. Plus a device like the SynthNV Pro takes up much less space and power.

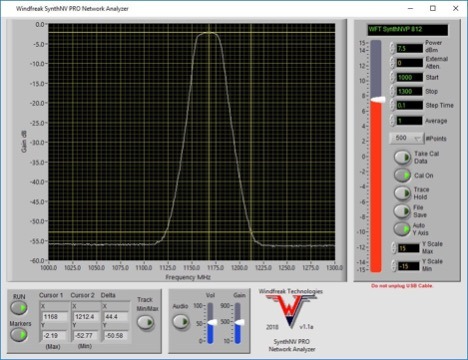

If a sweep output is still desired for human viewing, this can easily be seen with provided software on the controlling PC.